A Comprehensive Guide to Industrial Heat Pump Technology

Can your refrigeration plant meet your hot water needs and save you money on your boilers?

What's inside

Industrial heat pumps can capture industrial waste heat efficiently, reduce fossil fuel use and are 5 times more efficient than a steam boiler.

1.

How heat pumps can save money by recovering heat from waste energy

Refrigeration systems can run on a number of refrigerants but Ammonia for an all round application is the most versatile refrigerant, CO2 is a refrigerant that is really only suitable for low temperature applications.

2.

How the inlet pressure and discharge pressure will effect the COP

The effective COP will depend on the heat pump inlet pressure and the discharge pressure that is required to deliver the needed water temperature, but the COP is likely to range between 4 and 8 (higher is possible depending on application).

3.

How hot water can be uses in multiple ways within a purpose design system

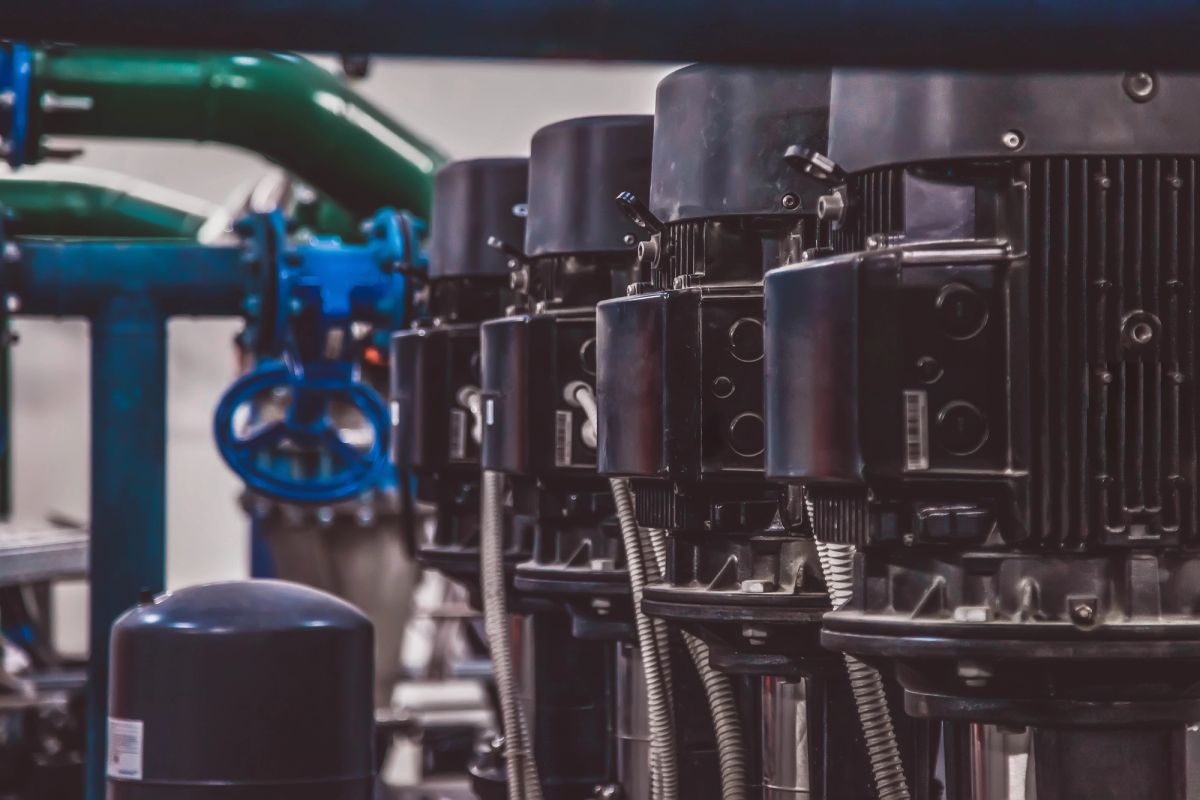

The first stage of the industrial heat pump is providing refrigeration to the facility via a secondary refrigerant. The heat being rejected via this first stage is either rejected to the atmosphere or is directly introduced into the second stage depending on whether there is a hot water requirement.

4.

How CoolPlanetOS can effectively map your refrigeration and heating needs

Balance is crucial for heat pumps. It is important that you have a consistent heat source when refrigeration is required to work. It is imperative to map the refrigeration system load against the load profile for the heating requirement.