Free

ReportPDF download

3 steps to processing heaven

Here's our guide to achieving a more efficient edible oils processing plant

What's inside

Our guide to achieving a more efficient edible oils processing plant

1.

The problems with tracking energy performance

Energy is a major element of your cost base (10-20% of gross margin) but it can sometimes feel like there is no way to control it.

2.

Lab tests are problematic

Significant improvements can be made in plant performance with relatively light touch interventions, i.e. interventions based on analytics, controls, optimisation and small projects.

3.

Really understand what drives energy consumption

While the overall predictive models shows something is off, it does not tell you exactly where to look. In depth models of each of the major components (DT, distillation, extractor, conditioners etc) must be built to get this insight.

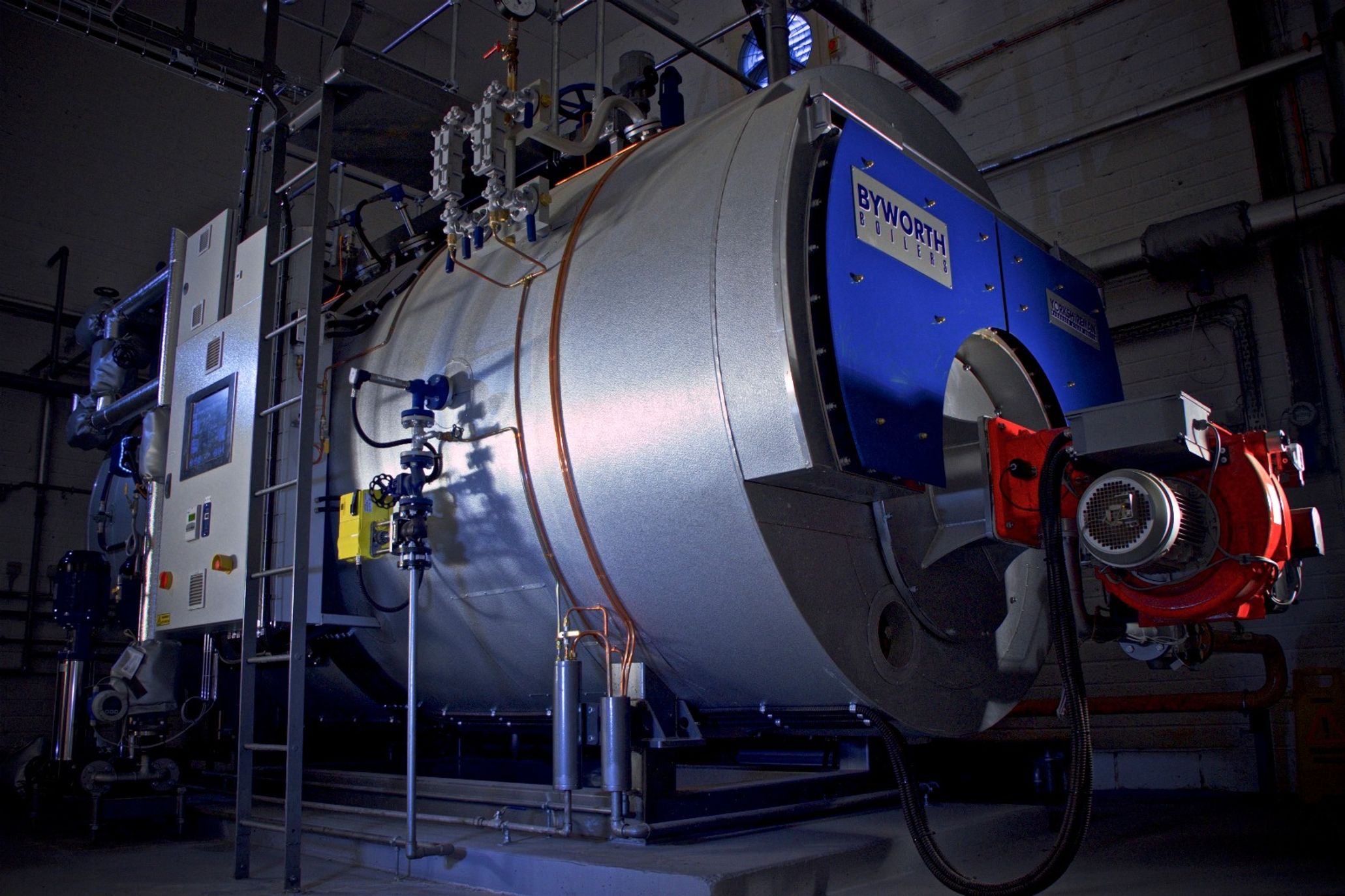

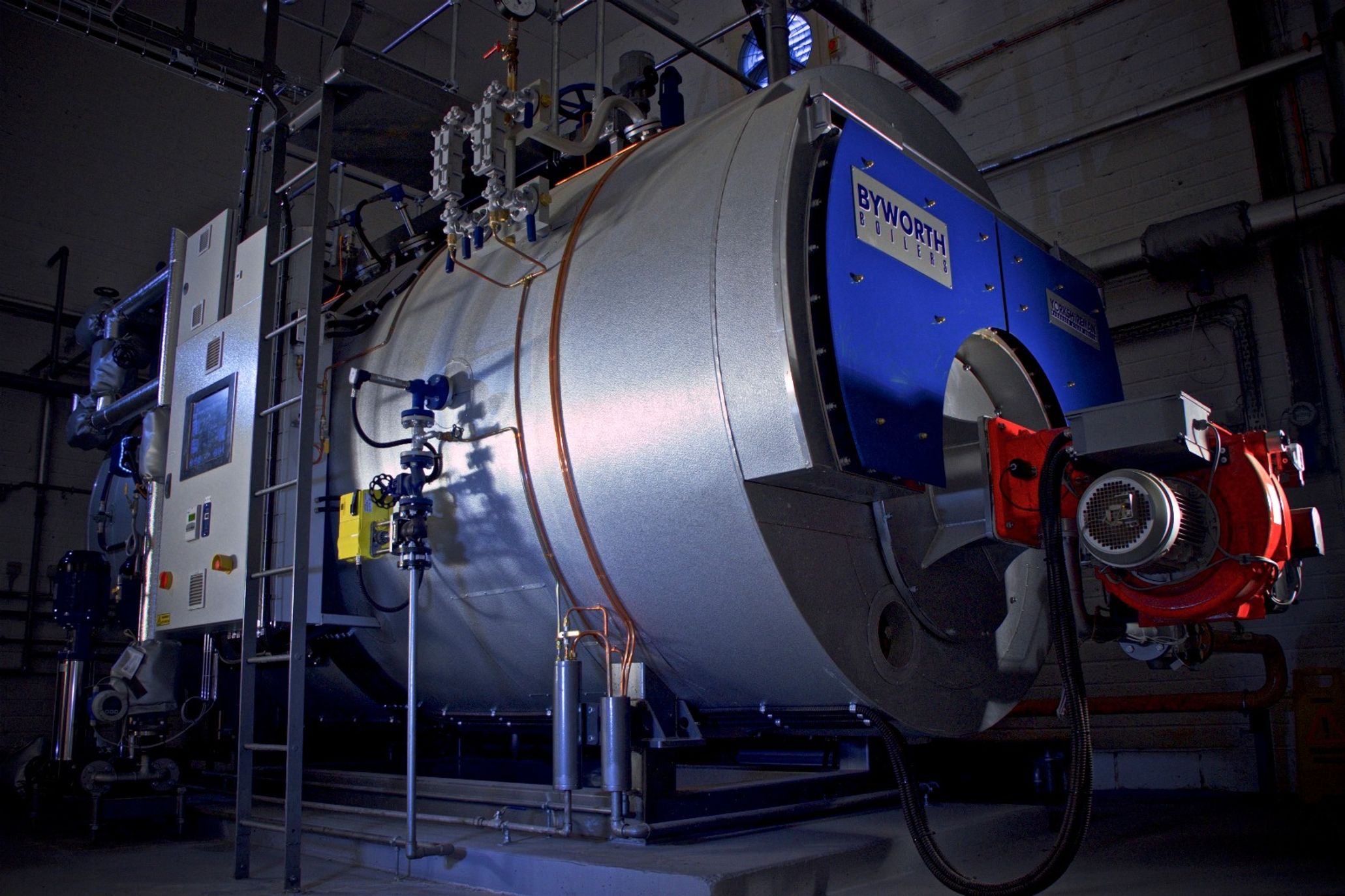

Overview An edible oil facility was having issues reliably maintaining steam pressures in the two...

Optimising a HEX evaporator created €110,078 in savings for an edible oils plant

Overview The edible oils plant conducted a caustic clean the HEX evaporator at its factory once per...