Heat Pumps in Ireland - The Facts

Heat pumps have been used in Ireland since the 1950s. They are an energy-efficient way to heat and cool your business and are now more popular than ever before. But which type is most suitable for your business and are they worth the investment?

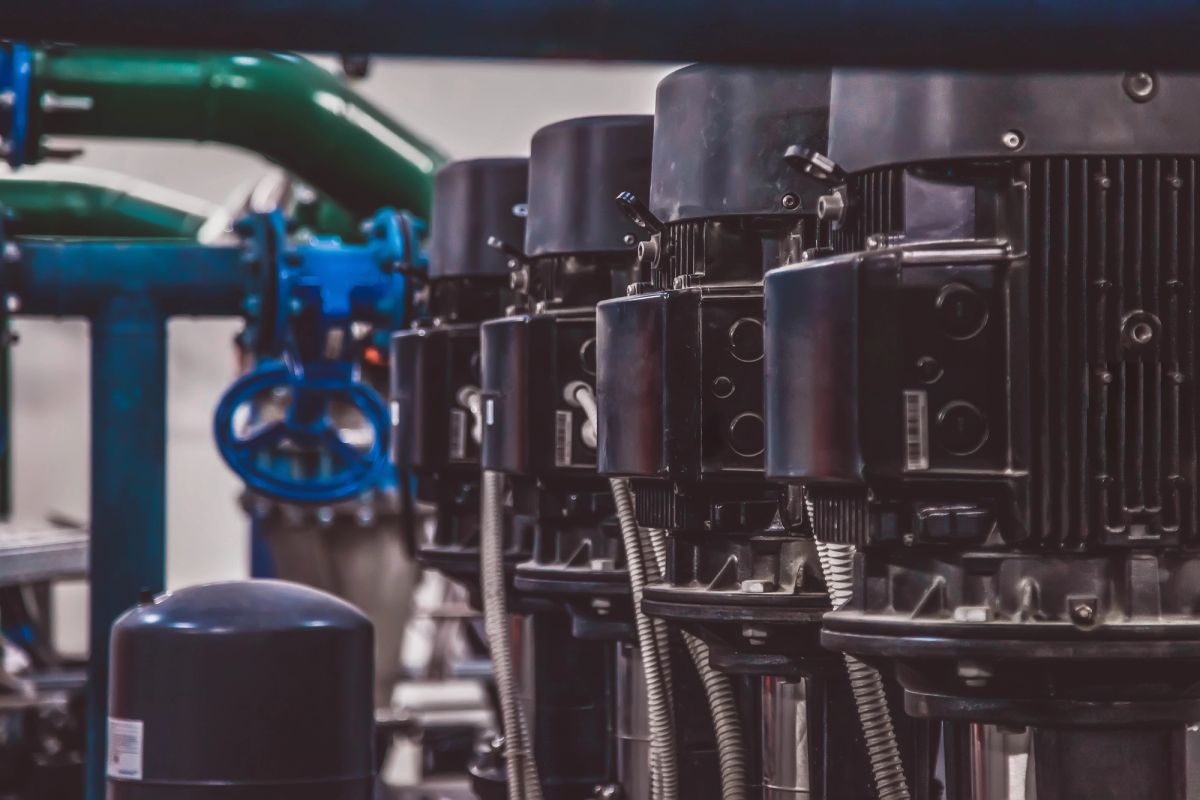

What is the functioning of an industrial heat pump?

A heat pump is in essence a refrigeration compressor that operates at higher pressures than a standard refrigeration compressor.

Rather than burning fuel to create heat, industrial heat pumps function by transferring heat from one location to another. Businesses may choose from four kinds of heat pumps:

1. High-Temperature Industrial Heat Pumps

High-temperature heat pumps, often known as industrial heat pumps, are heat pumps that can provide heat. Current heat pump systems are typically confined to heat supply temperatures ranging from 70°C to 80°C, although industrial processes are often built for heat supply temperatures ranging from 100°C to 200°C.

2. Industrial Air Source Heat Pumps

Air source heat pumps work by using electrical energy to transfer ambient heat from the air outside (even on a cold day) to an indoor space. There are two types of air source heat pumps - air to air and air to water. Air-to-water heat pumps can be used to provide hot water as well as heating.

3. Industrial Ground Source Heat Pumps

Ground source heat pumps, also known as geothermal heat pumps, are ideal for commercial buildings, particularly those that need cooling in the summer as well as heating in the winter. They draw heat from the earth, raise its temperature to provide heating and hot water.

4. Industrial Water Source Heat Pumps

Water source heat pumps work by extracting heat from a body of water such as lakes, rivers or streams and uses it to provide hot water and heating. They can also use water from industrial processes to produce hot water and heating, eliminating the need for steam.

Benefits of industrial heat pumps

Industrial heat pumps are an excellent choice for your factory or premises — here's why.

Reduce your carbon impact and boost your environmental credentials

Heat pumps are seen as a more ecologically friendly alternative since they emit less CO2. They offset fossil fuel consumption for generation of hot water or space heating efficiently to traditional methods (LPHW circuits, Direct fire burners, etc).

Reduce your company's energy costs

Instead of using fossil fuels and having your heating expenses determined by the cost of commercial gas, you'll just pay for the energy used to power the heat pump. There will also be decreased electricity load on condensers/cooling towers systems if rejected heat is the “prime”.

Increased safety

Heat pumps are more secure than combustion-powered heating systems. They are safe to use, and since they depend on electricity rather than fuel to create heat, they pose fewer safety risks than their competitors.

Reduced maintenance expenses

Heat pumps are very reliable, giving companies the peace of mind to go about their regular activities without worrying about inconsistent heating or the time-consuming responsibilities of unnecessary maintenance.

Free hot water

Can be used to provide refrigeration to a building/ process whilst at the same time generating hot water.

Role of Heat Pumps in Decarbonisation

Heat pumps convert heat from a low temperature (waste heat) to a high temperature (process heat). This is accomplished by using more energy, which is often electricity. The useful heat output is typically 2 to 5 times more than the electrical input, making heat pump implementation extremely effective for transmitting any kind and quantity of heat.

Industrial and manufacturing sites can use significant amounts of heat in their operations. Electrification of your heat through heat pump technology allows you to instantly move from fossil fuels and decarbonise your site.

Top 5 conditions when heat pumps make sense for decarbonisation

1. Green power supply: If the heat pump can be powered by green electricity (either direct from site generation or via PPA) this will deliver a significant decarbonisation result.

2. Waste heat available: If waste heat can be used to “prime” the heat pump this will maximize the efficiency (COP) of the heat pump thus reducing electrical consumption and thus running costs.

3. Price of carbon: As the heat pump (powered on green power) is reducing scope 1 carbon emissions ideally that carbon would have a cost attached to it, thus reducing heat pump payback and helping with carbon management .

4. Low-temperature heat loads: The lower the temperature the heat loads in the process, the better. The lower the discharge pressure from the heat pump the higher the COP and thus the lower the running costs.

5. High thermal energy prices: The heat pump is displacing thermal energy from boilers fired by gas or oil. Heat pumps make sense if the costs of these fuels are high.

How CoolPlanet can assist you with heat pumps

CoolPlanet can look after all design & install an industrial heat pump system to meet the needs of your business.

CoolPlanet’s industrial heat pumps can use renewable energy from the air, water or ground but also waste energy from buildings and processes to provide you with heating and cooling. They are cheaper to run than gas boilers, produce less carbon emissions and can even provide you with free hot water.